MIG (GMAW) Welding

MIG Welding is the most popular type of welding across sheet metal fabrication shops, due to its ease of use and its weld versatility. MIG welding equipment can be adjusted for many different positions and provides clean, precise welds for metal parts.

A brief overview of MIG Welding

MIG or Metal Inert Gas Welding is a widely used type of arc welding and a subtype of gas metal arc welding (GMAW). MIG equipment uses an inert gas to weld metals together. Welding is completed quickly and often uninterrupted, speeding up the production process and ensuring that you get your parts on time.

MIG Welding is versatile, able to join dissimilar metals, and work with a wide range of metals and alloys, including aluminum, magnesium, copper, titanium and other non-ferrous metals and alloys. It is most commonly used for sheet metal applications, though it can also be used in repair, as well as a range of other diverse applications.

Liberty’s MIG Welding Services

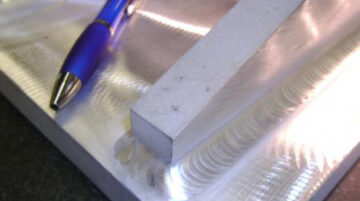

Liberty 3D provides precision MIG-welded fabrications from miniature to excess of 30,000 lbs. We both machine and paint your components, so that you don’t need to worry about outsourcing your parts to different companies for different services. Our welders are well-trained and highly experienced, and our methods leave little slag and minimal splatter–all of which we can easily clean to ensure your welded parts are clean, smooth, and precise.

Quality you can trust

Liberty’s welders are unmatched in our industry. We pride ourselves on our attention to detail in every part of the manufacturing process, from design to delivery. With quality inspection integrated into every part of our process, we ensure that your projects are completed on time, and meet or exceed your expectations.

Ready to get started?

Liberty 3D Technologies has been fabricating metal parts and prototypes for our customers for over two decades. We have expanded greatly since our beginnings, improving our quality management system and adding to our manufacturing capabilities, growing into a one-stop shop for all of your metal fabrication needs. If you’re ready to request a quote, or if you have any questions, don’t hesitate to contact us today!