TIG (GTAW) Welding

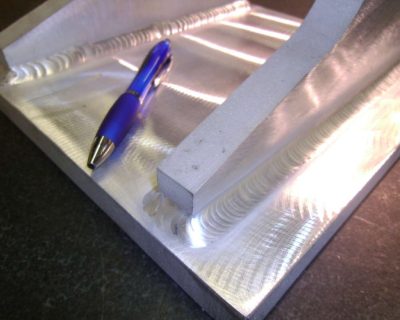

Liberty 3D’s TIG welding of stainless steel and aluminum is viewed by many food processing machine builders as state-of-the-art and world-class. Due to its difficulty, this type of welding requires highly skilled welders, and our welders take the time and effort to master TIG welding.

A quick overview of TIG Welding

TIG welding stands for tungsten inert gas welding, though the more accurate term for it is gas tungsten arc welding (GTAW). These types of welders use a non-consumable tungsten electrode to deliver the current to the welding arch, while an inert gas protects and cools the tungsten and weld puddle.

TIG Welding is a highly sophisticated and precise type of arc welding that produces the highest quality results of any other type of welding. There are many benefits to TIG welding, including clean, precise welds that require little to no cleaning when finished. Because the electrode isn’t consumed during the process, there is no possibility of slag introducing defects to the weld. TIG welds are highly resistant to cracking and corrosion even over long periods of time.

TIG Welding at Liberty 3D Technologies

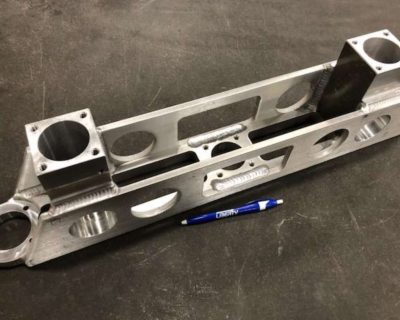

Our welders are highly skilled with all forms of welding that we offer, including TIG welding. Due to the cleanliness of our welds, we have provided these services to our customers in the Food Processing industry, where maximum cleanliness and precision are key. However, TIG Welding has many other applications as well!

- Any components made of nonferrous metals or metal alloys

- Parts with a small diameter

- Highly precise welds

- Exotic metals

- Thin-walled tubing

- Die and Tool Repair

Liberty is one of the most capable and widely recognized suppliers of TIG welding services. Our machining bay is fully equipped and we ensure that every weld is cleaned up and finished before it’s shipped to you.

Ready to get started?

Liberty 3D Technologies is your one-stop shop for all your welding and machining needs. For more information about our capabilities, or if you’d like to request a quote, don’t hesitate to contact us today with your requests!